Investing in the future…yours and ours…

Here at AFAB, we dedicate ourselves to strategic investment in advanced machining technology. Always looking ahead to identify the next big opportunity. After all, in the world of Precision Machining, progress is constant and timing is everything.

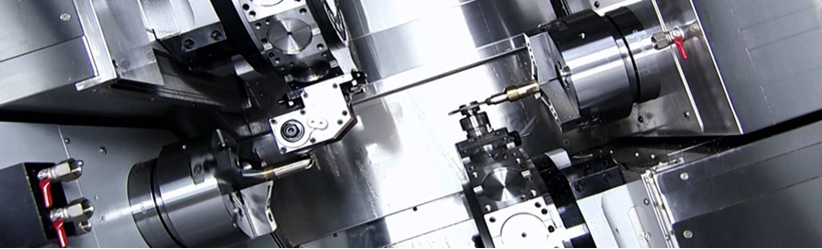

Multi-Task machining combines front and back CNC turning and milling. Tooling flexibility allows several cutting processes to be performed on one machine as opposed to having those same processes handled by multiple machines. When you can process an entire work piece, from solid raw material input to final machining, in a single setup, it saves time and money!

Multi-Axis machining enables shorter cutting tools to be used since the head can be lowered towards the job and the cutter oriented towards the surface. As a result, higher cutting speed can be achieved, and the vibration of the tool is reduced.

And this type of machining can also offer huge time savings in hole drilling. Drilling a series of holes with different compound angles is very time consuming. With multi-axis machines, the head or the part can be oriented along the correct axis for each hole automatically, allowing drilling to be completed more quickly and efficiently.

| REDUCE | INCREASE |

| Part Cost | Capacity |

| Lead Time | Flexibility |

| Human Error | Productivity |

| Out of Tolerance | Profitability |

| Multiple Inspections | Throughput |

| Set-Ups | Machining Accuracy |

| Transfers | Quality |

We look forward to hearing more about your multi-axis machining needs. Contact us regarding our material options, industry expertise and precision CNC machining capabilities.