We have achieved ISO 9001:2015 certification for our quality management system through Perry Johnson Registrars, Inc., demonstrating our commitment to providing our customers with the highest quality products and services.

The new standard changes the overall QMS structure to focus more on the harmonization with other ISO standards. We have added emphasis on leadership engagement, as well as a huge focus on risk-based thinking that continues to shape continual improvement throughout AFAB.

“ISO has become more than just a standardized way to run our business, but rather a complete mindset change in how it is run and how business is achieved. Customer focus is our highest priority and what better way to demonstrate it than through our continually improving quality management system.” –Larry Campbell, President.

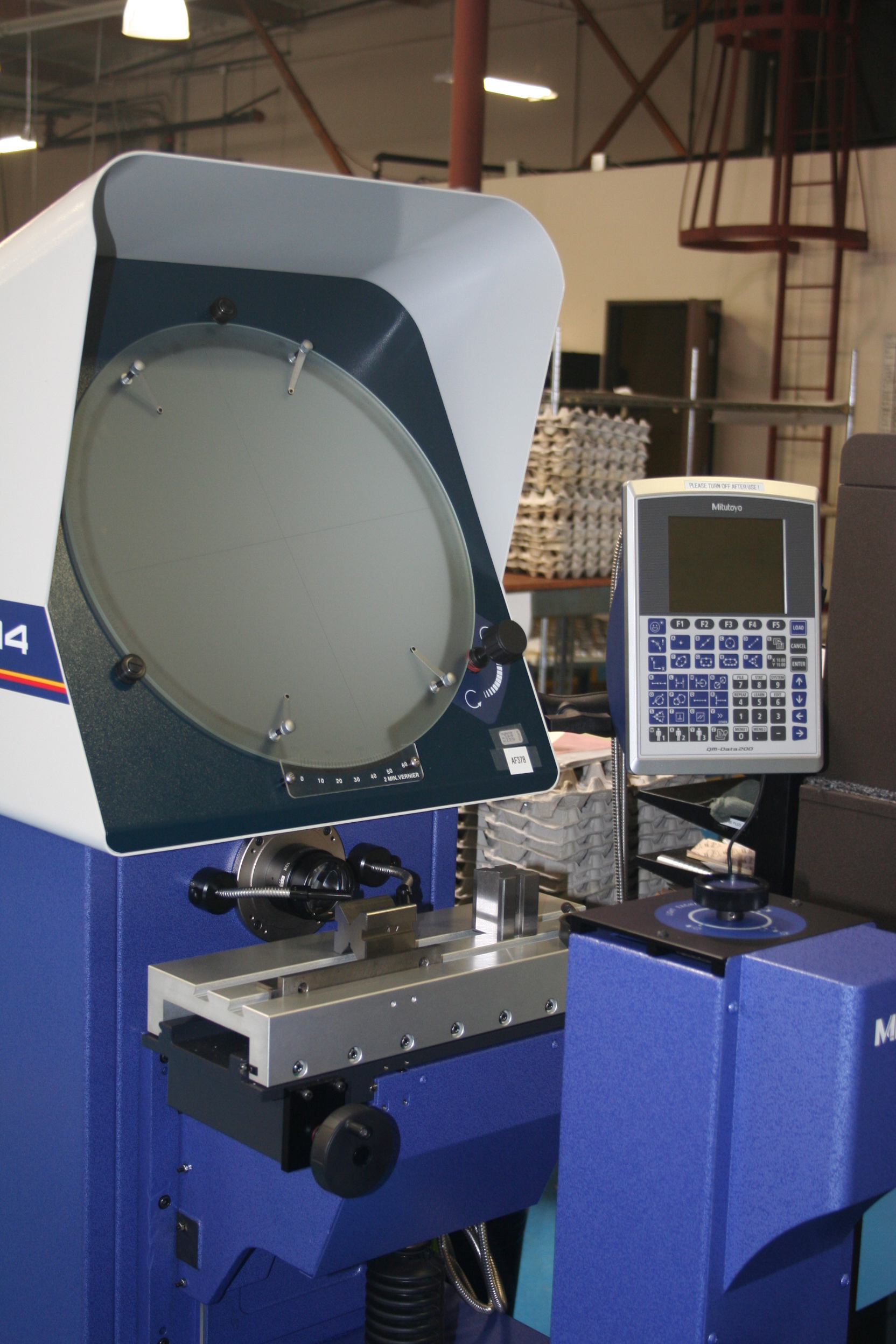

The ISO 9001:2015 certification validates our commitment to quality for the custom manufacturing of precision CNC machined parts and assemblies for the medical, dental and laser optic device industries as well as aerospace, transportation and defense sectors.